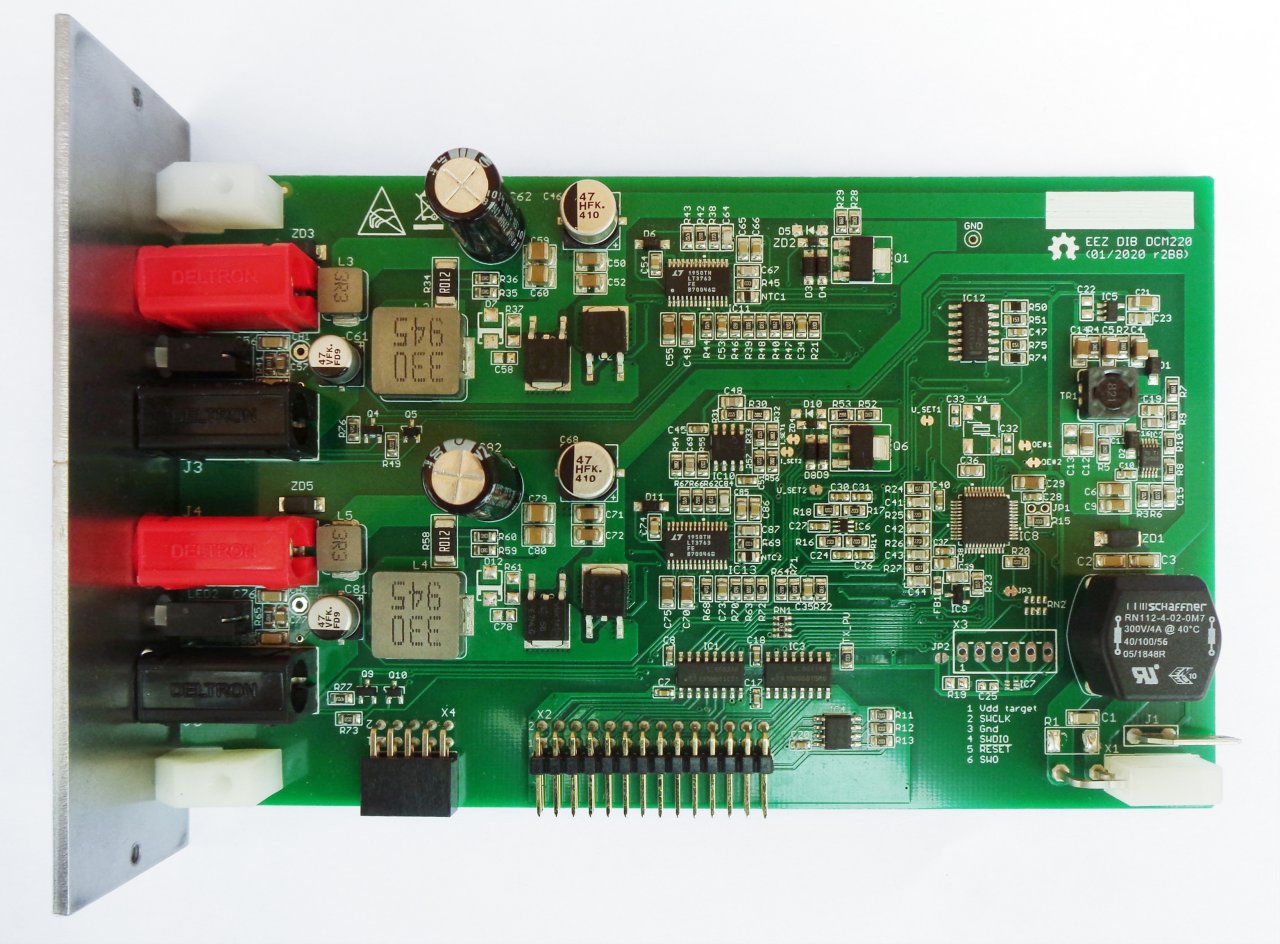

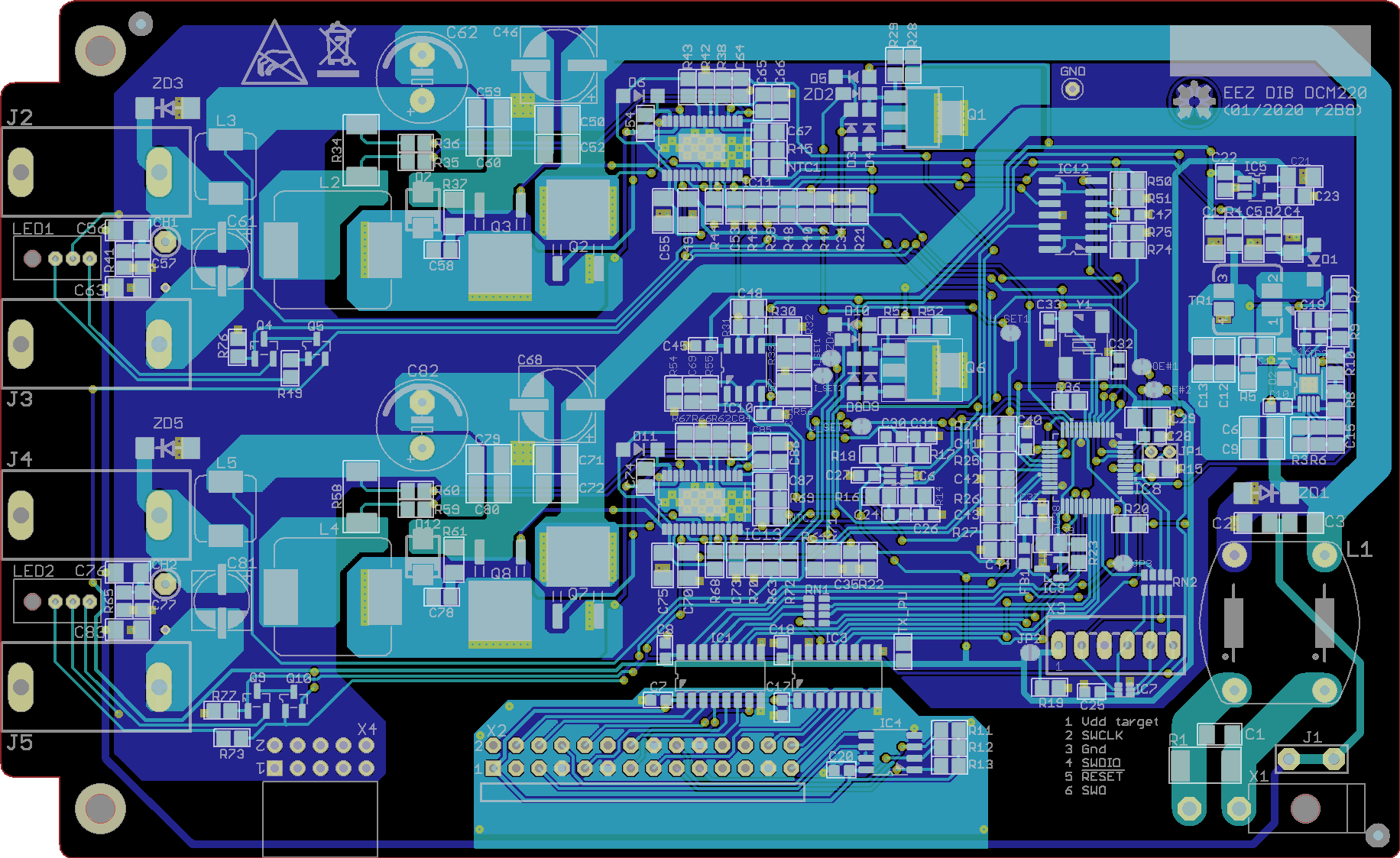

EEZ DIB DCM220 Dual output power module

|

Current version |

r2B8 |

|

Status |

Retired, use DCM224 as replacement |

|

PCB manufactured |

Yes (r2B8) |

|

PCB assembled |

Yes (r2B8) |

|

BOM |

Yes (TME, Mouser, Digikey, Farnell, RS) |

|

File repository |

https://github.com/eez-open/modular-psu/tree/master/dcm220 |

|

License |

|

|

Contributions |

|

Output power terminals |

Series |

Parallel |

Split rails |

Common ground |

|

No |

No |

No |

Yes |

Feature list

- On-board STM32F373C8T6 32-bit ARM Cortex®-M4 MCU, 64 KiB Flash, 32 KiB SRAM, LQFP-48 package

- Power input: 48 Vdc (e.g. Mean Well LRS-150F-48)

- Max. output power: 80 W per channel

- Voltage regulation (CV), 1 – 20 V. Voltage set resolution (U_SET): 12-bit, read resolution (U_MON): 15-bit

- Current regulation (CC), 0.3 – 4 A. Current set resolution (I_SET): 12-bit, Current read resolution (I_MON): 15-bit. Min. measured current: 100 mA

- Output enable (OE) with LED indicator

- CC mode LED indicator

- On-board power output terminals (Ø4 mm, 19 mm/0.75” pitch)

- 10-pin connector for Vout- coupling with other Power boards

- Galvanically isolated SPI bus for communication with the MCU board

- I2C EEPROM for storing board specific configuration and calibration parameters

- Upgradeable firmware via DIB v1.0 UART lines

- SWG/JTAG connector (optional)

- Two temperature sensors

- Dimensions: 155 x 95 mm, 2-layer PCB

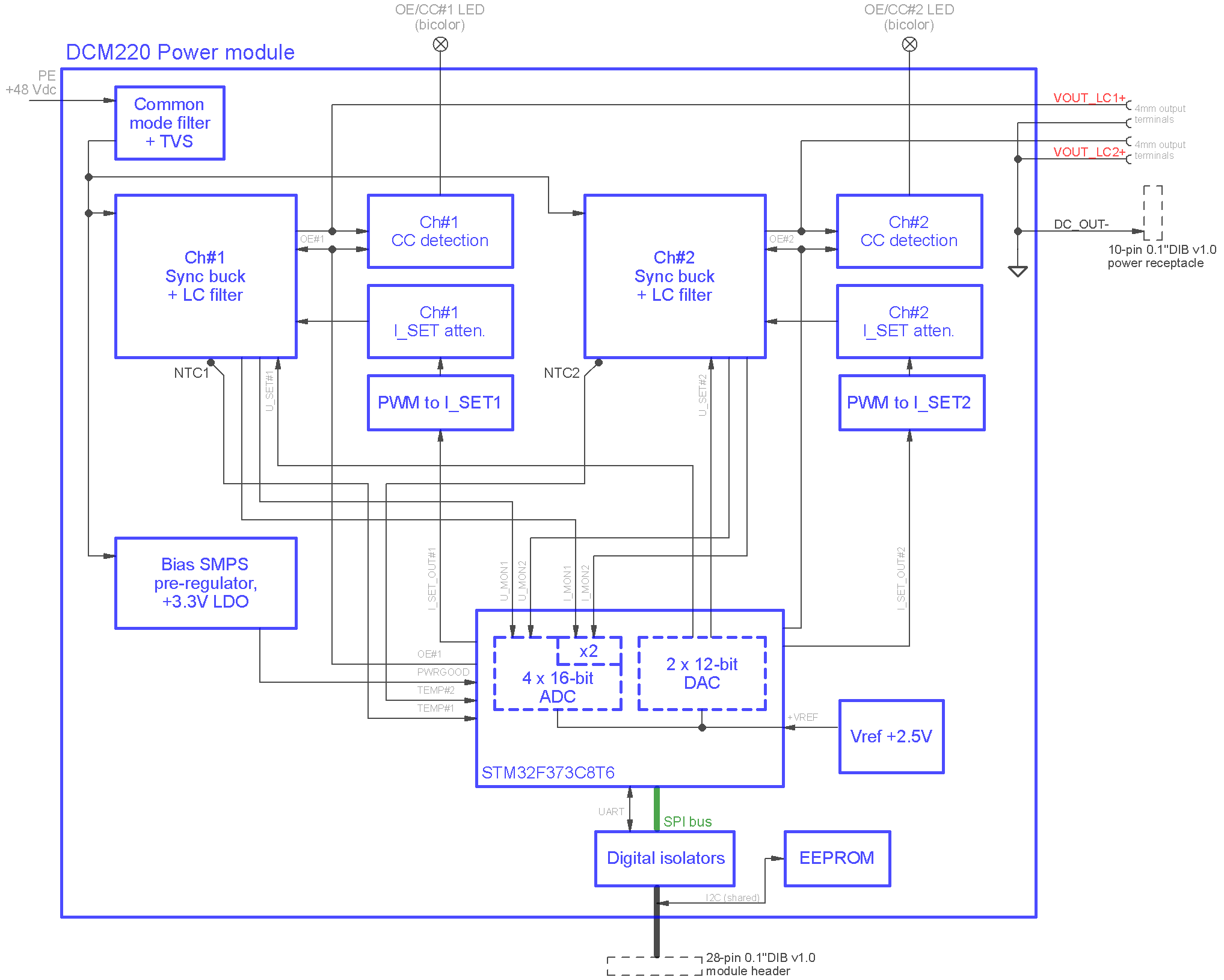

The DCM220 module is designed as a supplementary power module that offers two DC sources for up to 20 V and 4 A and it has no advanced features like the DCP405 module. The total combined output power is 155 W and is limited by the AC/DC converter used at the input.

Its outputs are floated towards the MCU module ground, however since they share the same DC power source they are not floated with each other so its outputs cannot be combined in series or split rails configuration as is the case with two single channel modules like DCP405.

This module can be installed in any of the BB3 slots in any combination with other modules, and when only they are used it is possible to get up to 6 DC source channels.

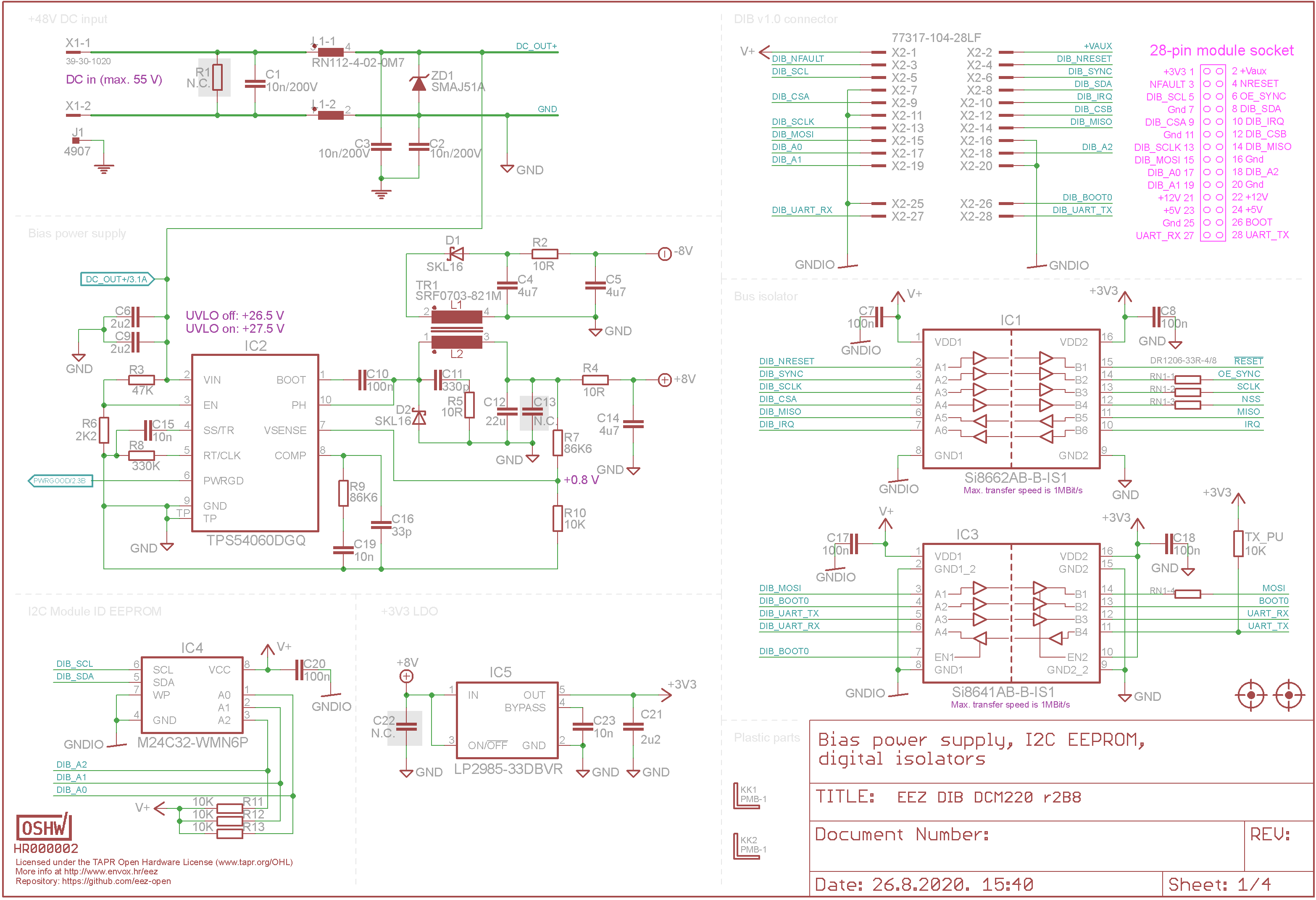

Bias power supply

The bias power supply is built around low power buck step-down converter (IC2), and thanks to coupled inductor (TR1) it provides both positive and negative rails of about +8 V for analog section. Digital section is powered with +3.3 V that is derived from LDO (IC5).

The IC2 also provides POWERGOOD signal that indicates MCU what is module’s power condition. It is related to UVLO (under-voltage lockout) functionality that is controlled with voltage divider consists of R3, R6. Therefore the step-down converter will cut-off power when input voltage drops below +26.5 V, and starts again when it rises above +27.5 V.

EEZ DIB interface

The DCP220 module interface with the MCU module is accomplished over the 28-pin 0.1” right angled header (X2). Since its power output has to be isolated (“floated”) all digital control lines has to be isolated. Therefore two digital isolators (IC1, IC3) are used.

Onboard I2C EEPROM (IC4) provides storage for module-specific information such as its ID, calibration data, working hours counters, etc. Please note that it is on the “A-side” of the isolation barrier, because the same I2C bus is shared among all modules (that includes AUX PS module, too). It address is defined by R11, R12 and R13 pull-up resistors and ground connections on the backplane.

The MCU (IC9) on Fig. 6. is a SPI “slave” that communicates with the “master” MCU on the MCU module.

Power channel outputs can be synchronized with power outputs on the other modules thanks to OE_SYNC signal that is also controlled by “master” MCU.

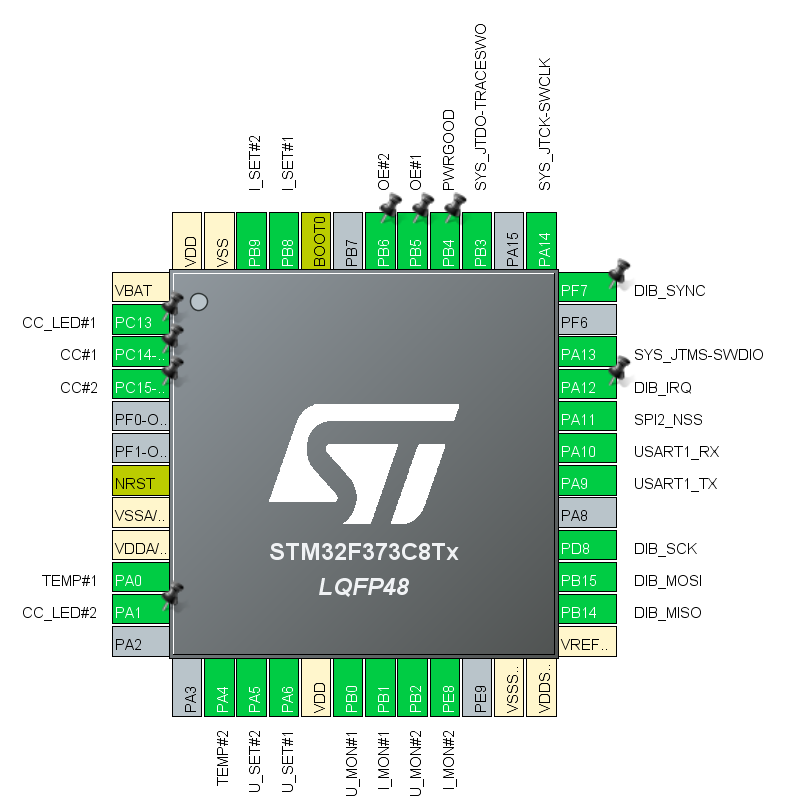

Digital control

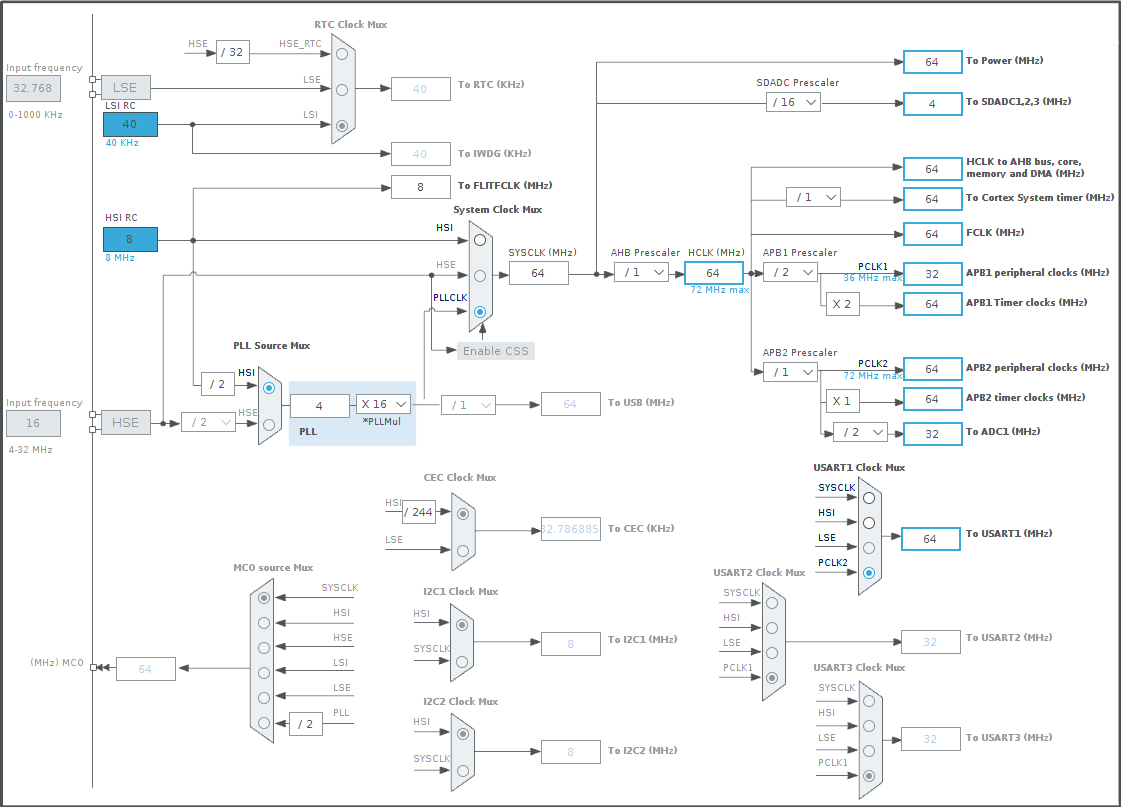

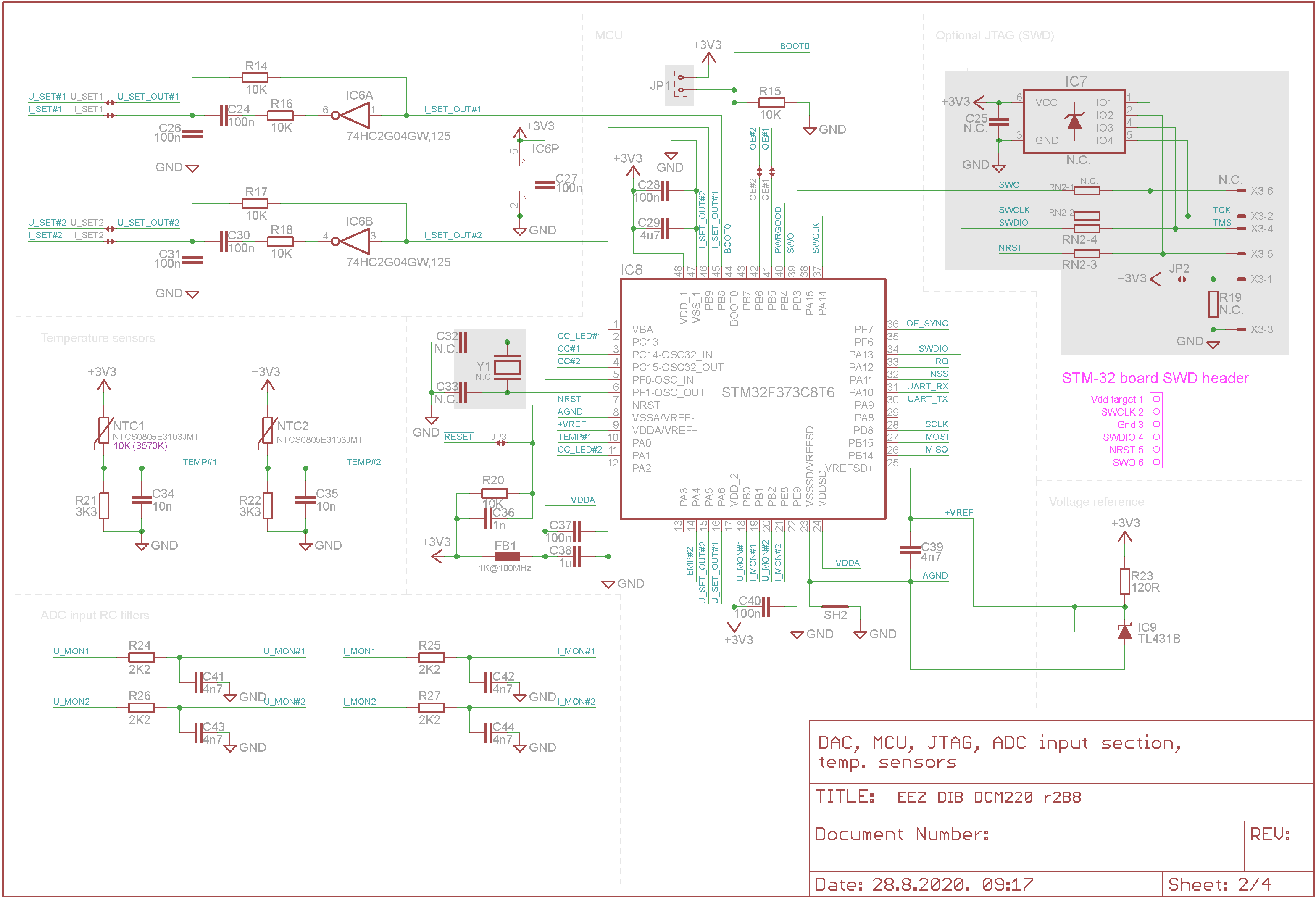

The DCM220 comes with STM32F373C8T6 (IC8), a mainstream mixed signals MCUs ARM Cortex-M4 core with DSP and FPU with 64 KiB Flash, 72 MHz CPU and MPU. It’s also featuring 12-bit DACs and 16-bit Sigma-delta ADCs (with inputs multiplexer). Its pin assignment and clock settings are shown in Fig. 4 and Fig. 5.

Controlling DCM220 power channels require two DAC channels (one for programming voltage and current) that gives four channels in total. Since selected MCU comes only with three DAC outputs, two are used for set output voltage (U_SET_OUT#1, U_SET_OUT#2) and remaining two required to set output currents are generated using MCU’s PWM outputs.

16-bit ADCs are used for monitoring output voltage and current. Power output voltage value is derived with simple voltage dividers (R40, R47 on Fig. 7., and R64, R71 on Fig. 8.) that are set to provide +2.5 V for full scale. ADC voltage reference (+VREF) is provided by IC9.

Power output current value is measured by DC/DC controller (IC11, IC13) and available on its ISMON pin. Since its output range is from zero to only +1.5 V, a gain of x2 is selected in firmware on ADC’s current inputs (I_MON#1, I_MON#2).

Output voltage programming

The output voltage is programmed by affecting FB pin voltage that is set by voltage divider R39, R46 on channel 1 and R63, R70 on channel 2 (the DAC outputs are brought via R48 and R72). The output voltage on the channel 1 can be calculated taking into account the following equations:

|

|

Vout = VFB + IR41 * R41 |

(Eq. 1) |

|

|

IR41 = IR48 + IR50 |

(Eq. 2) |

|

|

IR48 = VFB / R48 |

(Eq. 3) |

|

|

IR50 = (VFB - VDAC) / R50 |

(Eq. 4) |

The VFB voltage for selected DC/DC controller is 1.2 V, while VDAC voltage range is from 0 to +2.5 V. Substituting Equations 2 through 4 into Equation 1 yields:

|

|

VOUT = VFB * (1 + (R41 / R48)) + (VFB - VDAC) * (R41 / R50) |

(Eq. 5) |

From Equation 5, it can be seen that the maximum output voltage occurs for the minimum DAC voltage, and vice versa. We can calculate what is a max. output voltage by applying VDAC = 0 V:

|

|

VOUT = 1.2 * (1 + (30 kΩ / 3.9 kΩ)) + (1.2 - 0) * (30 kΩ / 3.6 kΩ) = 20.43 V |

Output current programming

Conversion of PWM to analog signals for current programming is accomplished with DC filtering and additional ripple cancellation (IC6) as proposed by Stephen Woodward (see EDN article Cancel PWM DAC ripple with analog subtraction, November 28, 2017).

The output current programming value comes to CTRL1 input of the DC/DC controller and it has to be in range from 0 to +1.5 V. Therefore an op-amp (IC10B, IC10A) is used to attenuate current programming signal by 0.45 since its range is from 0 to +3.3 V.

Temperature is measured by two NTCs (NTC1, NTC2) that make voltage dividers with R21 and R22. NTC’s are positioned near DC-DC controllers (IC11, IC13). Voltage dividers outputs vary with temperature and they are brought to ADC inputs TEMP#1 and TEMP#2.

The MCU firmware could be uploaded by set BOOT0 input to +3.3 V during the power-up or reset and use UART for communication with programmer (that could be “master” MCU on the MCU module). Additionally, for development purposes it is possible to solder X3 connector and used ST-LINK compatible in-circuit debugger/programmer.

If an STlink debugger is to be used, resistor array RN2 (22 – 47 Ω) will also need to be installed.

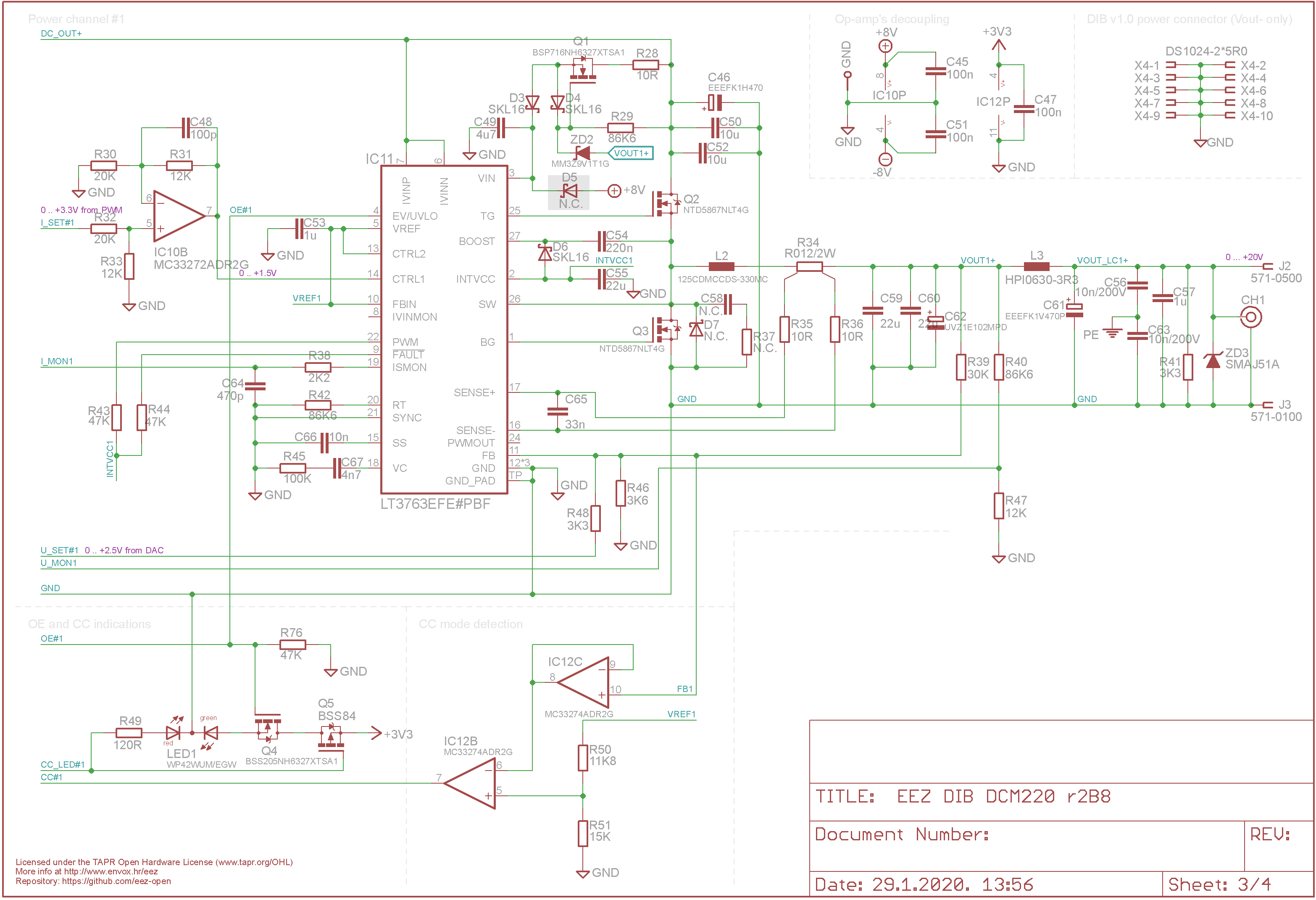

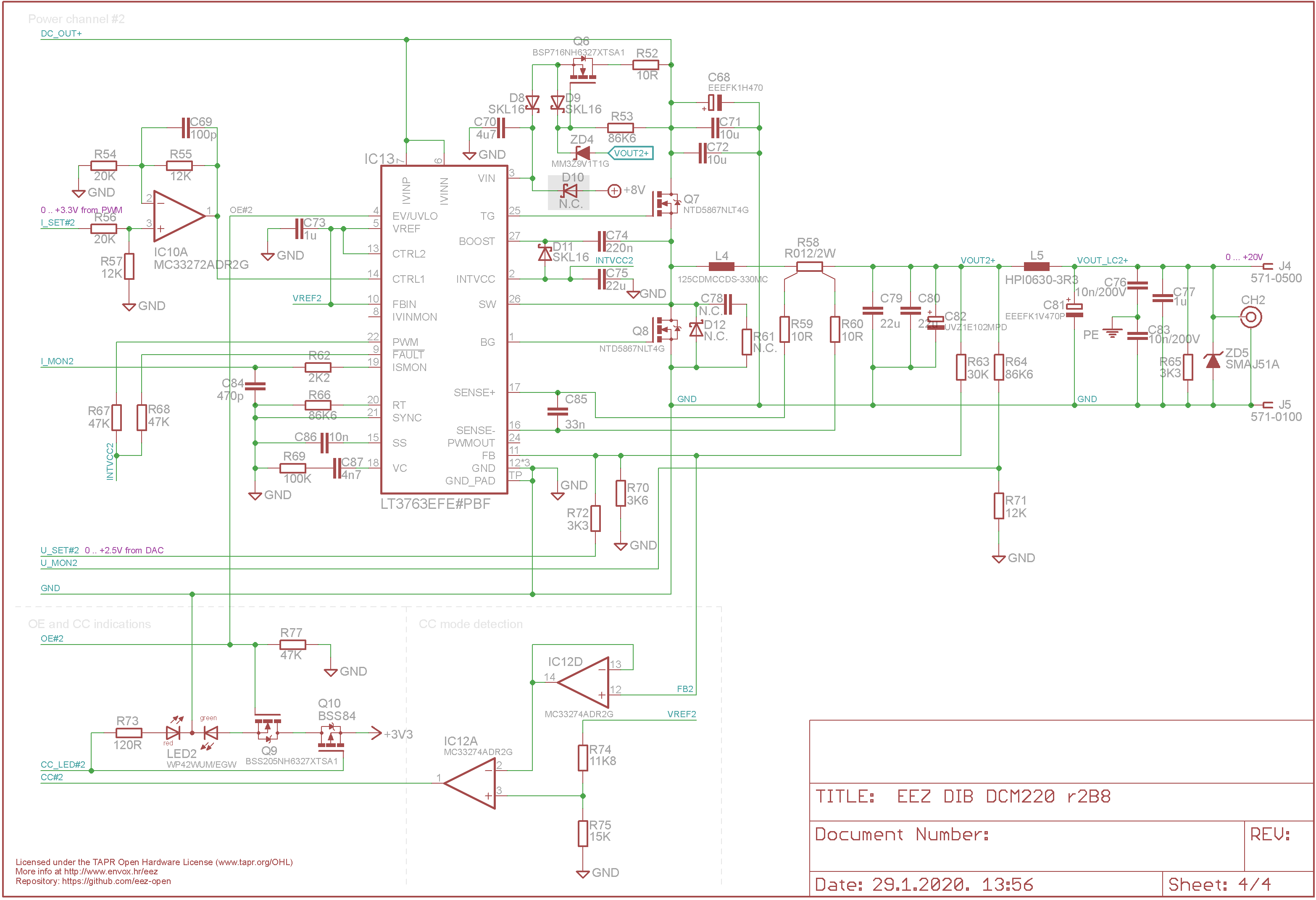

Power channels

The DCM220 module comes with two identical power channels based on 60 V high current step-down synchronous LED driver controller (IC11, IC13) as shown on Fig. 7 and Fig. 8. They are sharing the same power input of +48 Vdc and consequently share the same ground.

The LT3763 comes current programming and monitoring that can be used for digital control and can work in CV (Constant Voltage) or CC (Constant Current) mode.

Unfortunately, it does not provides an indication of the mode of operation. Therefore the CC mode indication is accomplished on presumption that it currently does not works in CV mode and that is when voltage on the FB pin is below +1.4 V. Comparators (IC12B, IC12A) are used to check voltage level on the FB1 and FB2 pins that are buffered with IC12C, IC12D to minimize interference with the CV control loop.

Comparator’s outputs are brought to MCU’s digital inputs CC#1, CC#2 that can be used by firmware to indicate that on the TFT display or by activating red LEDs of bicolor LED1, LED2 (via Q5, Q10). Activation of that LEDs depend also of channel output state, and its disabled by when channel’s output is disabled.

Power outputs state are directly controlled by MCU digital outputs OE#1, OE#2 brought to DC/DC controller’s EV/ULVO input and that signals are used to drive green LEDs of bicolor LED1, LED2 (Q4, Q9).

The DC/DC converter is equipped with internal regulator with Vin as a power input and provides +5 V on its output that is used for powering internal logic and to some extent external circuit if total consumption does not exceeds 60 mA. Measured internal consumption is about 22 mA that with voltage drop of 43 V requires that almost 1 W is dissipated. It comes in package with thermal pad, but that is not enough if huge underlying PCB cooling plane cannot be provided. That usually asks for at least 4-layer PCB that could increase production costs.

The usage of 4-layer PCB is avoided by adding simple voltage regulator (Q1, Q6) on the Vin pin. It is tracking power output voltage and insure difference of at least +7 V (defined by ZD2, ZD4 and Vgs(th) that is 1.8 V max. for the selected MOSFET) that is required for normal operation. Therefore the internal regulator will be supplied with about +7 to +27 V instead of continuous +48 V that reduces its dissipation significantly, or better to say, move it to the voltage regulator’s MOSFET that comes in bigger package and can be cooled down much easier.

When DC/DC converter is disabled, voltage on the Vin rises to the power input value (+48 V). To avoid damage of the MOSFET (Q1, Q6) in that case, diodes D3, D4, and D8, D9 as protection are added.

Power outputs are equipped with LC filters (L3, C61 and L5, C81) to reduce ripple and noise and protected against over-voltage and reverse polarity with TVS diodes ZD3, ZD5.

PCB layout